Sustainability in industrial production

How the sector can live up to its special responsibilities

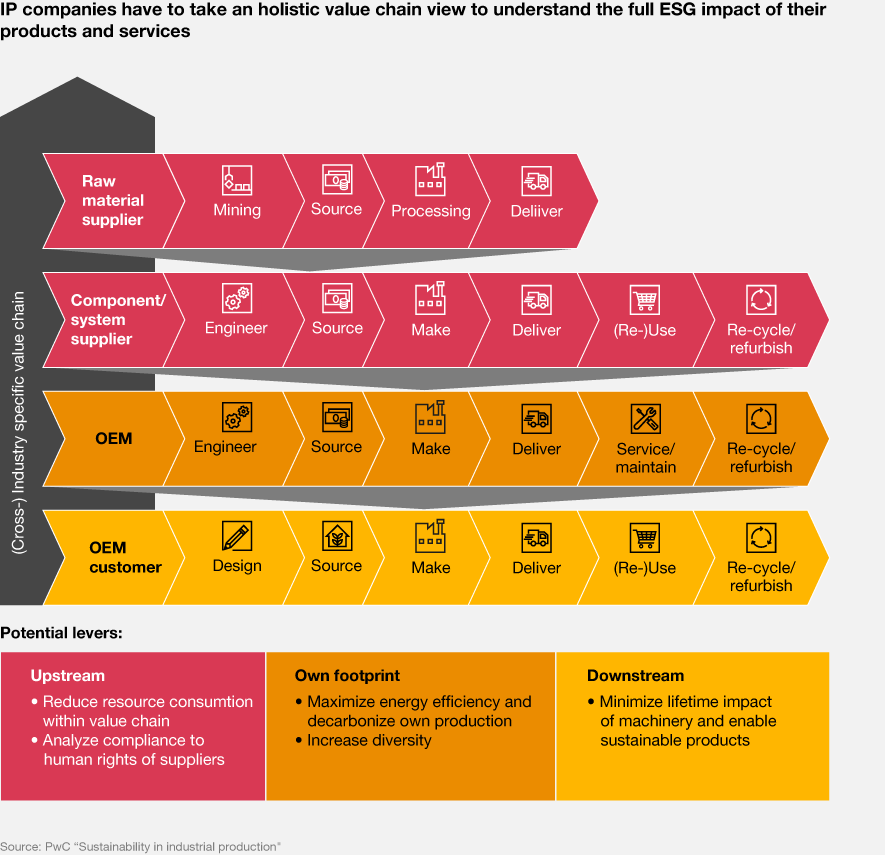

The fight for sustainability in industrial production has been going on since the industrial revolution. However, against the background of global warming, the topic of sustainable production is currently receiving more focus than ever – because industry is particularly resource-intensive and energy-intensive. When energy and heat consumption are included in the calculation, industry is responsible for around 40 percent of global carbon dioxide emissions. A large proportion is related to basic materials such as steel, aluminium, plastic and cement. Estimates expect global consumption of these materials to be two or even four times higher by the year 2050.

“With global value chains and high levels of resource-intensity, industrial production has a major responsibility for the environment – and is also an important lever in efforts to achieve a more sustainable and environmentally compatible production in the future.”

Industrial production is transforming

Industrial production is currently going through a transformation. This opens up a wide range of opportunities for sustainable solutions:

- Changing customer expectations are increasing the speed of innovation and generating demand for new manufacturing processes e.g. plastic-free, recyclable packaging.

- Digitisation and automation are creating connected factories that can save resources and produce goods more efficiently e.g. by enabling 3D-printing of customised components and reducing the use of materials and resources.

- Supply chains are becoming increasingly global and multi-layered, which also makes them more complex and more vulnerable – as the Covid-19 pandemic has shown, and as the growing impact of climate change will show in the future. Manufacturing networks are changing dynamically, including a trend for re-localisation of parts of the value chain.

- Operational excellence and cost-efficiency can secure a company’s ability to compete and can also contribute to sustainability – through more efficient equipment, for example.

- Companies face increasing regulatory requirements and investor expectations, particularly related to sustainability (e.g. CSR guideline, EU taxonomy). Rising transparency is increasing pressure and causing substantial changes in production activities and along the entire value chain.

Your situation

The ticking time bomb of sustainability

Many manufacturing companies have set sustainability targets, and offer sustainable products and solutions. However, these are often comfortably within the boundaries of what is possible. There are many reasons for this.

Typical challenges include:

- Strategy: There is no clear strategic focus on material topics or no identifiable differentiation from other players in the market.

- Transparency: Reliable data about emissions or employee-related topics is missing or unused.

- Integration: Companies cannot connect the topic of sustainability to their business strategy. Horizontal and vertical integration in the company is inadequate.

- Targets: Companies set targets that are not sufficiently ambitious because they are focused on what is possible today and lack a long-term perspective.

- Implementation: The company has not defined the responsibilities, resources, costs and processes necessary for effective implementation.

Our services

Leading companies are actively driving progress on sustainability

Many companies are being driven by regulatory requirements and are not exploiting the full potential of sustainability. We are supporting our clients in tapping into particularly attractive opportunities in the following areas:

- Sustainability strategy and transformation

- Climate change and decarbonisation

- Sustainable supply chains

- Sustainable products and the circular economy

- Impact valuation

Sustainability strategy and transformation

A clear strategy that is derived from the material topics for the company and its stakeholders is the basis for anchoring sustainability into all processes and areas of a company. This creates the right conditions for minimising sustainability risks, such as those within the supply chain or broader value chain. It also helps companies to earn and build trust among customers and employees, while cutting costs and creating a clear differentiation against competitors. This puts companies in a strong position to tap into sustainability-related market opportunities.

Climate change and decarbonisation

The industrial sector faces expectations to decarbonise its use of electricity, heat and cooling. Leading companies are setting “Science-Based Targets” that are proven to be derived from the overarching climate targets – and that are also audited and binding. Some companies are setting “Net Zero” targets, while others are even leading the way to climate positivity. By improving efficiency, leveraging synergies, embracing electrification and using green gases, it is possible to produce more sustainable goods with a reduced carbon footprint.

Sustainable supply chains

Manufacturers must take a very close look at their global value chain in terms of social and environmental considerations. For companies in the chemicals and metals industries, for example, around 60 percent of climate emissions are generated outside of their own production sites. For machinery & equipment producers, this figure stands at almost 90 percent. The supply chain also accounts for the majority of air pollution, water consumption and land use.

Sustainable products and the circular economy

A large proportion of environmental impacts are generated when customers use products, particularly when this involves machines and equipment with a long service life. For this reason, sustainability must already be taken into consideration during product development, and the suitability for a circular economic model should be planned into every stage in the entire product life cycle. Through measures such as targeted reuse of components or entire machines, it is possible to reduce the environmental footprint – while also cutting costs.

Impact valuation

Companies must comply with increasingly demanding requirements for transparency about their ESG footprint, as well as rules for sustainability reporting (e.g. value chain laws, EU taxonomy, CSR guidelines). Transparency and consistent sustainability reporting that reflects business-relevant factors create the foundation of a targeted sustainability strategy.

Our promise

Our Sustainability Team will join you on every step of your journey to sustainable industrial production.

Our work is guided by three fundamental beliefs:

- From strategy to implementation: An effective sustainability strategy must be closely connected to the overall business strategy, embedded within the organisation and implemented consistently.

- Industrial knowledge and sustainability expertise: Our team includes consultants with many years of experience in industrial production, who work closely with sustainability experts and representatives from your company.

- Holistic perspectives: We take a comprehensive view of sustainability and leverage internal and external experts, as well as stakeholders from our global network.

Let’s work together to transform your company into a driving force for sustainability in industrial production.

Further insights in the field of industrial production

Sustainability in the chemicals industry

The chemical industry plays a central role in global efforts to tackle the biggest challenges facing society and environment – such as climate change. This industry is now striving to move away from a reactive and compliance-driven approach, and to focus on value creation instead.

Do you have any questions?

Contact our experts

Contact us